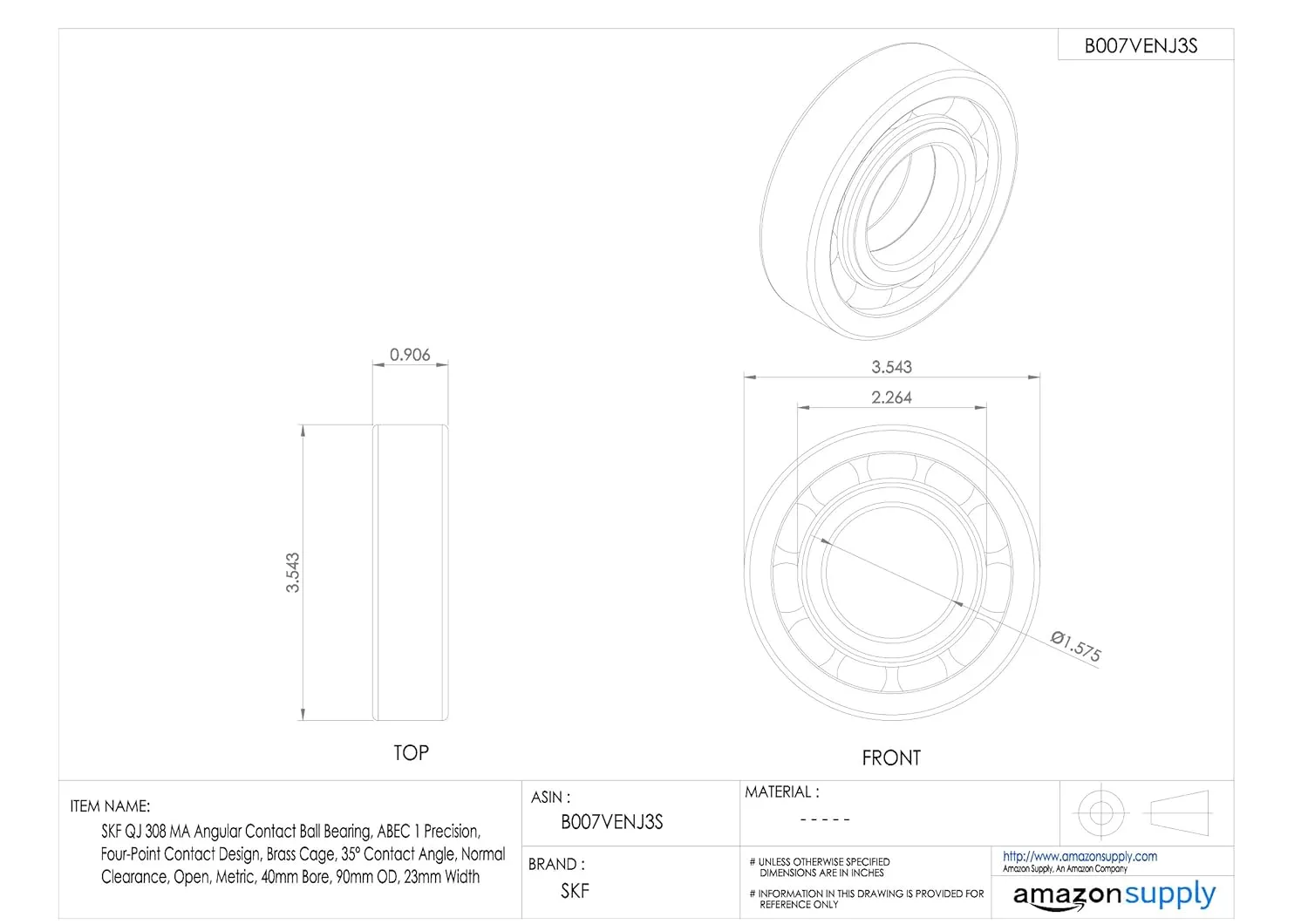

- Single-row angular contact ball bearing, supporting bidirectional thrust loads, and combined loads where thrust load is predominant

- Ball contact angle of 35 degrees relative to the inner and outer raceways increases thrust load capacity

- Open configuration for lubrication applied in place

- Brass cage evenly spaces balls for reduced friction, vibration, and noise

- ABEC 1 tolerance ratings for accuracy and low rotational speeds

The SKF angular contact ball bearing with four-point contact design is an open bearing and has a 35-degree contact angle, brass cage, normal clearance rating, and Annular Bearing Engineering Committee (ABEC) 1 precision. It supports bidirectional thrust loads, and combined radial and thrust loads where the thrust load is predominant, while taking less thrust space made of low-alloy, through-hardened carbon chromium steel for durability and resistance to deformity. The 35-degree contact angle of the balls in relation to the raceways gives the bearing a greater capacity for supporting thrust loads over bearings with a standard contact angle of zero degrees. Its open design facilitates lubricating the bearing in place and dissipating heat. This bearing has a brass cage to prevent the balls from coming into contact with each other during use, reducing friction, vibration, and noise. The bearing has a normal axial internal clearance designation, making it suitable for applications where the load and speeds do not result in thermal expansion. This clearance provides latitude for self-realignment and compensates for static and dynamic alignment errors. Additionally, the running accuracy and performance levels for this precision bearing meet Annular Bearing Engineers' Committee (ABEC) 1 (ISO P6) standards for a moderate level of precision. ABEC-rated ball bearings are manufactured to tight dimensional tolerances, making them useful in applications that require high accuracy, high rotational speeds, and increased operating efficiency. This angular contact ball bearing is for use in commercial and industrial applications including pumps and compressors, automotive drives, gearboxes, and printing machines, among others.

Rolling bearings use rolling elements to maintain the separation between moving parts to reduce rotational friction and support radial and axial loads. These elements can be one of the following types: ball, cylindrical, spherical, barrel, needle, spindle, or tapered. All rolling bearings are open, shielded, or sealed. Sealed bearings are lubricated with oil or grease in the bearing factory, while open and shielded bearings are meant to be lubricated in place, with periodic reapplication of lubrication, based on use. The shield protects the working parts of the bearing from environmental debris that may be introduced and could reduce the ball bearing speed and lifespan. Rolling bearings are used in a range of applications from agricultural machinery to conveying equipment, robotics, dental equipment, elevators, rolling mills, ship rudder shafts, and aggregate crushers, among others.

SKF manufactures bearings, seals, and lubrication systems for automotive, OEM, energy, and other and industrial applications. The company, founded in 1907, is headquartered in Gothenburg, Sweden, and meets International Organization for Standardization (ISO) TS 16949 and 9001 standards for quality assurance.

- Date First Available : July 15, 2012

- Manufacturer : SKF